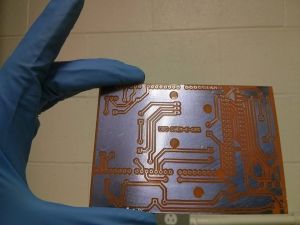

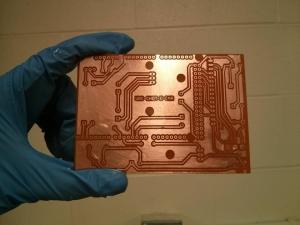

Two years ago we had some issues with poor electrical connections coming loose in transit (or randomly). Stock circuit boards worked in the mean time, but it was difficult to get a lot of functionality in a small space. Therefore we started making our own printed circuit boards. Learning to make circuit boards provides an opportunity for us to learn some more design software. With a bit of trial and error, we found a method that works quite well for us. If you want to find out more, check out our fb page and ask us a question.